Beading effect as a method of assessment of the water repellent property of the construction material surface

Prolongation of service life of new buildings, retention of performance properties and reduction of repair costs are the most important problems, which are solved even during the construction process. The water infiltrating into construction materials proves to be one of the main reasons of the breakdown and deterioration of their thermal-insulating properties. Traveling in pores, the water gradually dissolves salt crystalls, which, with periodical moistening and drying-up, results in the change of material structure and its stress degradation [1]. In this way, the hydration of mineral ingredients of the material causes formation of partially soluble crystalline hydrates. The growth of crystalline phase in the porous volume (almost fivefold [2]) gives rise to high internal (crystallization) pressure, which in turn disturbs the material structure and reduces its strength. Also, the material moisture content to a great extent accounts for its heat-transfer capacity. As the water content rises, the material heat transfer jumps. It can be explained by the fact that the heat-transfer capacity of water contained in the pores of the material is 20-fold higher than that of air in the pores of medium size [3]. The heat-transfer capacity will increase more sharply if the wet material is frozen. It occurs because the heat conduction coefficient of ice is 4 times greater than that of water and hence, 80 times greater than that of air in the material’s pores. So, to preserve performance characteristics and extend the life time, the material should be protected against water.

For the purpose of this article, all current methods of protection of buildings against water can be divided into two groups. The first one is water proofing. It covers practically all known methods. It is characterized, among other things, by forming a rather high water barrier and also by sharp reducing of vapor permeabilty of the media boundary line, which is, for instance, unacceptable for the outer contour of residential buildings. The second group is water-repellency treatment, which makes it possible to prevent infiltration at rather low values of aquatic environment pressure. In some cases, it is sufficient for a reliable protection of constructions, the above ground protective structures being the most important example.

In case of water-repellency treatment the material’s pores are coated with a thinnest layer of hydrophobic film without clogging the pores, which results in the reduction of electrostatic interaction between liquid and solid molecules.

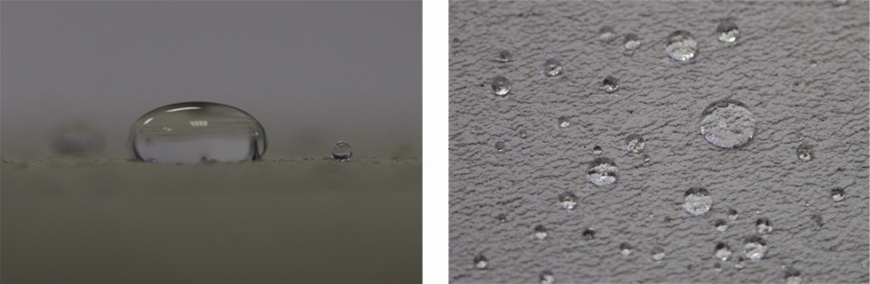

The so-called lotus effect (beading effect, dew effect) serves as a striking example of applying water-repellent agents to the surface of any porous construction material of mineral origin whether it is concrete, bricks, natural stones, decoration plaster or paving slabs. The said effect occurs as a consequence of the very low surface wettability. (Fig. 1)

Fig. 1 Lotus effect

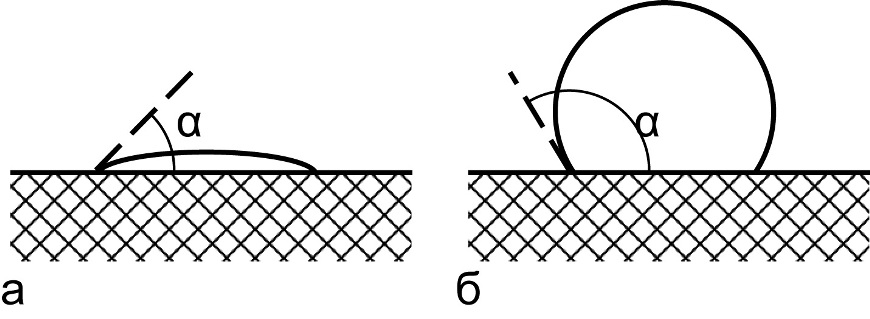

The surface wettability is characterized by a contact angle of wetting. (Fig. 2) If a liquid droplet on the solid body surface takes the shape to form an acute contact angle, then the solid body surface shall be referred to as hydrophilic. If the contact angle is obtuse (beading effect), the surface shall be referred to as hydrophobic [4].

Fig. 2 Contact angle of wetting: а – hydrophilic surface, α<900

б – hydrophilic surface, α>900

Some consumers and other market participants share the view that the beading effect occuring on the surface of construction material gives grounds to make a decision on its water absorption ability. The authors of this article disagree with such data correlation. In their view, natural conditions leading to wetting of vertical surfaces of enclosing structures are not taken into consideration (precipitation with rain, slanting rain, washing under pressure, etc.) in this case. Apart from this, relying on this opinion may blur the absence of the main indicator characterizing the water repellent efficiency, i.e. reduction of water absorption by the construction material treated with this water repellent. It may happen because the indicator is overshadowed by the beautiful visual effect.

While assessing the beading effect, the material’s pores inner surface is under atmospheric pressure and the outer one, in addition to the atmospheric pressure, takes hydrostatic pressure of the droplet. Since the liquid pressure depends on the column height of this liquid it becomes apparent that the pressure created by the drop is sufficiently small. When operating above ground buildings under natural conditions (precipitation with rain, slanting rain) the wind flow pressure is the main power factor, which causes a multiple increase of the pressure differential on inner and outer surfaces of the pores. Consequently, the water drops may be forced into the pores under the impact of this pressure differential [5]. In such a manner, the wind speed will exert great influence on the water absorption by the material of such structures under natural weather conditions.

In our view, in order to determine a water absorption indicator of the hydrophobizated material it is necessary, instead assessment of the beading effect, to employ a method taking into account the said power factors. RILEM Test Method II.4 (American version - ASTM E 514) is most suitable for this. It was developed by RILEM (Reunion Internationale des Laboratories D’Essais et de Recherches sur les Materiaux et les Constructions, Paris) and recommended for use to assess water absorption ability of buildings’ out walls over a certain period of time under natural weather conditions [6].

In this country, this method is referred to as the non-destructive analysis based on Karsten method. The essence of this method is to determine an exact amount of water permeating into the unit surface area per unit time [7]. During trials according to the Karsten method a graduated tube (Fig. 3а) is fastened to a vertical surface of the tested material. Then the tube is filled with water to the required height (the filling depth correlates with the wind speed [7]) and volumes of sorbed water are determined after certain periods of time (Fig. 4б).

We have conducted a series of experiments with the aim to check a presense of correlatin between the wetting angle value, measured by means of experimental observation of the beading effect, and the water absorption value determined by using the Karsten method. The experiments were conducted with the aid of concrete test cubes treated with different silicone liquids for rendering water-repellent.

The contact angle of wetting was determined by analyzing photographic images of the sitting drop.

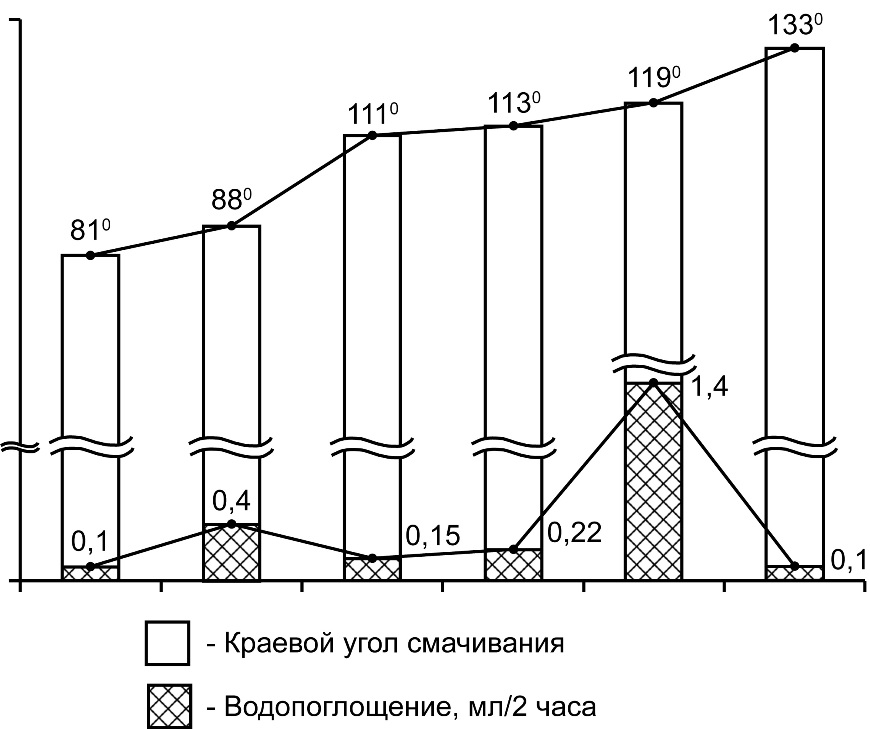

Table 1 shows the experiment results.

Table 1

|

Hydrophobisator (organosilicon fluid), No. * |

Contact angle of wetting |

Water absorption, ml/2 hours |

|

1 |

88° |

0.4 |

|

2 |

119° |

1.4 |

|

3 |

113° |

0.22 |

|

4 |

81° |

0.1 |

|

5 |

111° |

0.15 |

|

6 |

133° |

0.1 |

* Organosilicon fluids 1-6 – samples of silicone liquids for rendering water-repellent available in the Russian market.

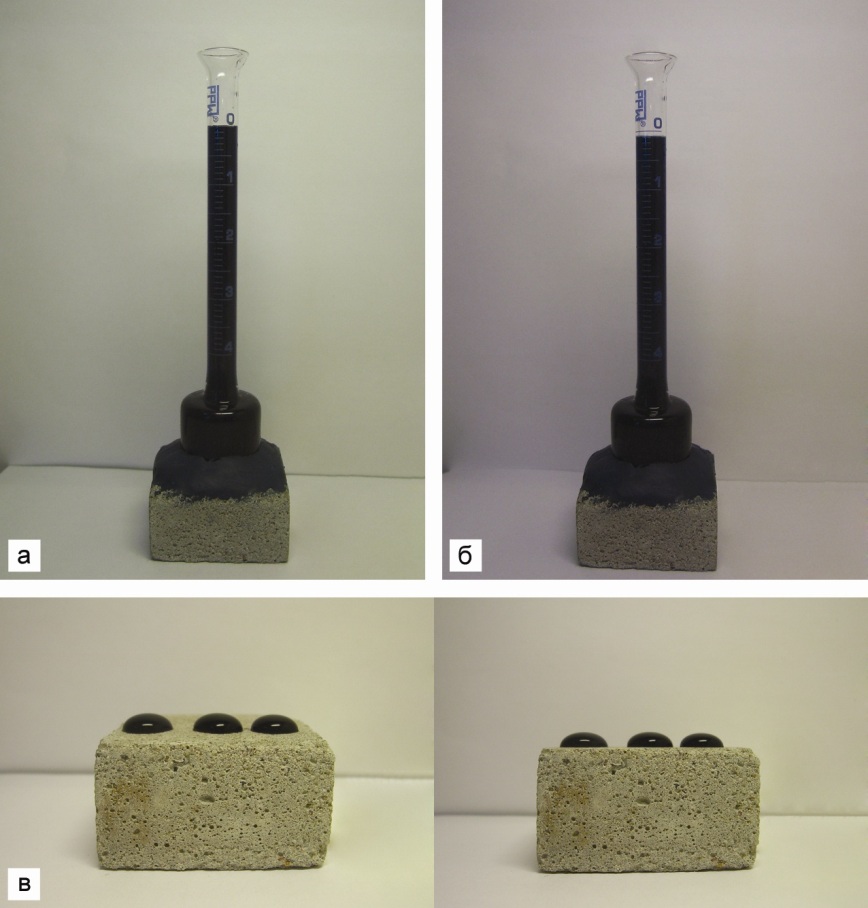

Fig. 3 Organosilicon fluid No. 4: а – beginning of the experiment; б – water absorption after 2 hours; в – beading effect (contact angle <90°)

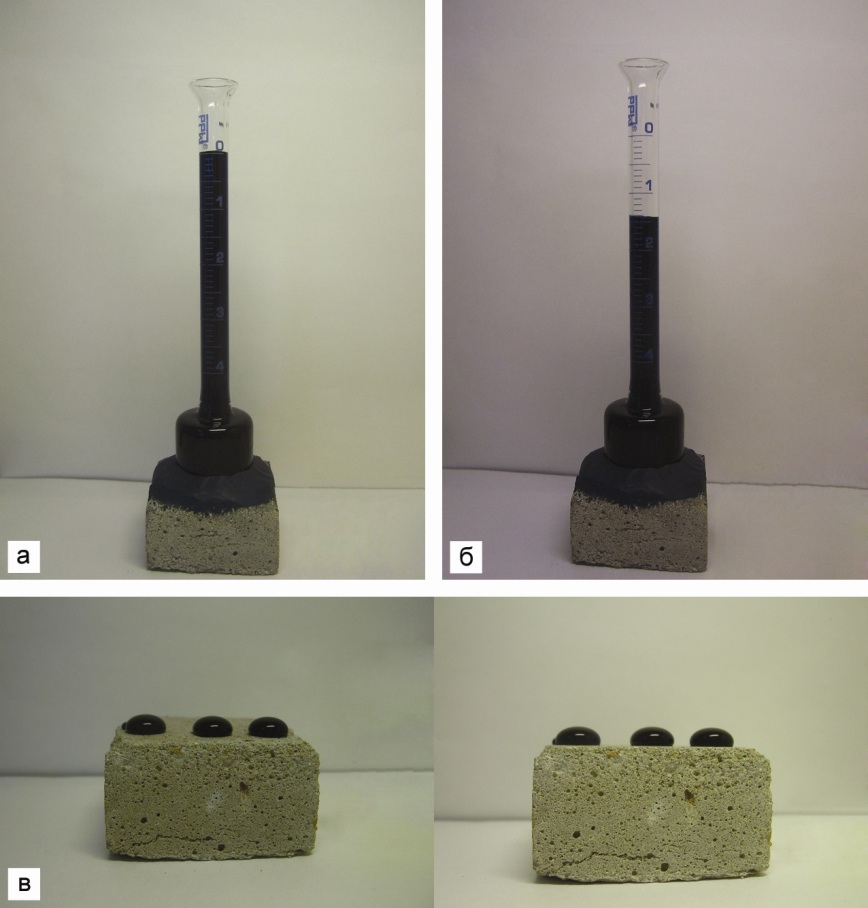

Fig. 4 Organosilicon fluid No. 2: а – beginning of the experiment; б – water absorption after 2 hours; в – beading effect (contact angle >90°)

As is clear from the data obtained, the correlation between the beading effect and the water absorption may be different for the material. The cubes, treated with water-repelling agents Organosilicon fluid 6, 5 and Organosilicon fluid 3, give a good beading effect and low water absorption; those treated with Organosilicon fluid 2 give a good beading effect and high water absorption – (Fig. 4); those treated with Organosilicon fluid 4 (Fig. 3) and Organosilicon fluid 1 give a bad beading effect and low water absorption.

In this way, we confirmed our doubt that there is a correlation between the beading effect and the water absorption (Fig. 5). The water drop rolling down the surface is not indicative of low water absorption and the drop spreading over the surface is not indicative of high water absorption. In other words, it is impossible to advance a view of the hydrophobisator efficiency judging by behaviour of the drop on the surface of the porous material treated with this repellent. Only the Karsten method results in a correct assessment of the quality of water-repellency treatment of the surface, while the beading effect is only a spectacular but not mandatory illustration of the hydrophobisator’s performance.

In the end of this article, we would like to point out that based on the presented experiment results the Company’s engineering personnel upgraded Performance Specifications for hydrophobizators, manufactured by our plant, in the context of engineering performance and production control methods.

Contact angle of wetting

Water absorption ability, ml/2 hours

Fig. 5 No dependence between the beading effect and water absorption

Literature:

1. М.В. Соболевский, О.А. Музовская, Г.С. Попелева Свойства и области применения кремнийорганических продуктов, М., «Химия», 1975

2. А.В. Волженский, Ю.С. Буров, В.С. Колокольников Минеральные вяжущие вещества (технология и свойства), М. Стройиздат, 1979

3. В.Л. Миков, А.Ю. Куренкова Справочник монтажника. Том 1. Теоретические основы монтажа, СПб.: НИУПЦ «Межрегиональный институт окна», 2006

4 А.А. Алентьев, И.И. Клетченков, А.А. Пащенко Кремнийорганические hydrophobizators, Киев, ГИТЛ УССР, 1962.

5 T. Ritchie. Rain penetration of walls of unit masonry // Canadian Bulding Didgest – 1960

6. Rilem Test № II.4. Water absorption under low pressure (pipe method). // RILEM Commission 25-REM, Tentative Recommendations, 1980.

7. Bauchemie-Handbuch fur Stud. Praxis, g. Auflage Verlag C.F. Muller, Karlsruhe 1992.

Authors:

Павлов В.И. Руководитель исследовательской лаборатории ООО «САЗИ» Pavlov V. I. Head of Research Laboratory, SAZI, LLC

Простякова А.И. Технолог ООО «САЗИ» Prostakova A. I Process Engineer, SAZI, LLC